Robotic Process Automation allows for the real-time aggregation of data from many sources and the automation of complicated operations. I’ll walk you through a typical industry process in the blog article that comes after and show you how Intelligent Robotic Process Automation Use-case could be able to make this process simpler.

One of the main areas of attention for any O&G company’s daily operations is vessel planning or berthing planning. It is essential for operational effectiveness to guarantee that there is clear and real-time visibility regarding the existing and planned locations of each vessel because large oil tankers move between ports on a daily basis.

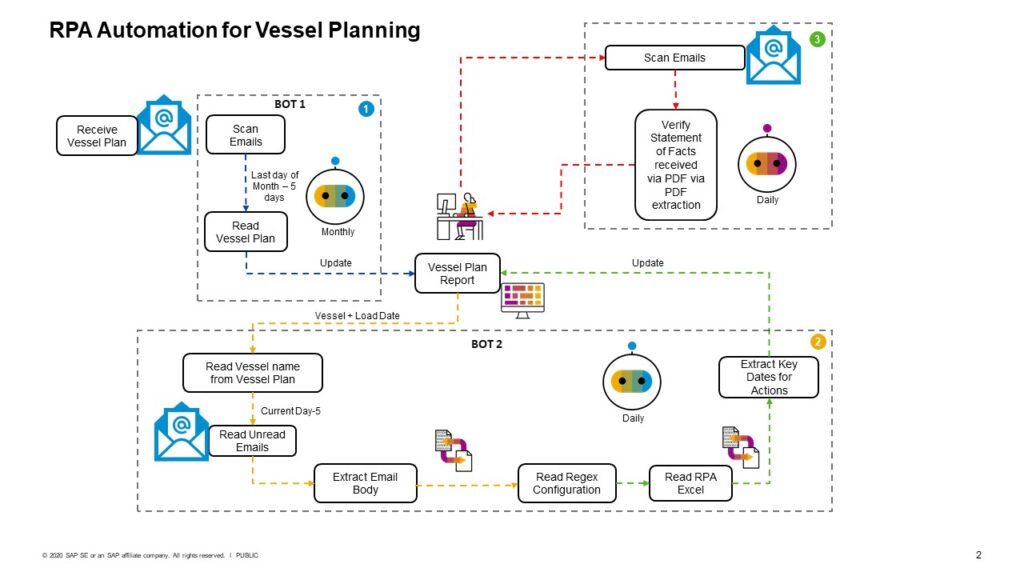

The following is a typical use-case workflow that is common in Oil and Gas Industries.

- A tanker plan for the upcoming month is received at the importer’s mailbox

- Based on the received tanker plan, the receiver prepares a new Plan (Lets call this, the Port Plan), based on the proposed dates, ports and quantity

The next steps are sent via multiple emails, which include details like

- Vessel Arrival Date and time, Notice of Readiness (NOR), Berthing date and time. Connection of loading arms, Cargo loading completion date & time, Disconnection of loading arms, Vessel Name, Bill of Lading, Grade wise Cargo Quantity, Expected Time of Arrival at Disport, Expected Time of Berthing at Disport, Expected Time of Sailing off at Disport, Vessel Arrival Date and time, Berthing date and time, Connection of loading arms, Cargo loading completion date & time, Disconnection of loading arms, Sailing off date & time.

All these details will be typically sent via mail with a definite subject line.

A user normally reads these details after receiving them in numerous emails, and after reading them, the user manually updates the port plan whenever a new email is received.

After receiving all the necessary data, the receiver creates a summary, which is subsequently shared with all the relevant job holders for Product Planning.

The amount of manual work can be significantly reduced if this process can be automated to assure real-time changes to the tanker plan reports, leading to an effective, integrated, and seamless vessel planning procedure.

RPA Automation to the rescue

The above illustration gives a general idea of how Intelligent Robotic Process Automation Use-case can be utilised to streamline the entire process, which could be carried out by three bots that are scheduled to run in the background (as unattended bots).

Bot 1

Bot 1 reads the Tanker plan for the following month, which is delivered towards the close of each month. This robot will read the mailbox in search of a subject related to the Tanker plan. After receiving the mail and reaching its predetermined trigger, the bot will read it, download and extract the data from the excel file, and update the port plan for the following month.

Bot 2

Bot 2 will be set to run more regularly than Bot 1, and since these emails are coming from various sources, the subject to be searched would be looking for the specific subject line with wildcards. The information from these emails is then extracted, read by the bot using Regular Expressions (REGEX), and placed in the Port Plan along with the extracted information.

Bot 3

The Statement of Facts received through email as a PDF file afterwards serve to verify the Port Plan that has thus been developed. A Bot that can be scheduled to read this every day would do so. Following verification via a Statement of facts, the same Bot then calculates and updates the Port Plan with the number of days required for discharge and demurrage. The bot then distributes the summary information to other job holders.

With only 3 Bots, which may be used as unattended bots, the tasks that were carried out by different receivers across several days can therefore be streamlined and automated.

By automating the repetitive operations, this will lower the manual error rate and lower the number of repeats.

No comment